news

Contact Us

Kunshan Suliyou Precision Mould Co.,Ltd.

Contact:Nanle Yuan

Telephone:15950165093

E-mail:yuannl@youkaitech.com

Chengdu Youkai Precision Mould Co.,Ltd.

Contact:Zhenghua Gu

Telephone:18190821310

E-mail:guzh@youkaitech.com

High standardization of mould parts can meet the needs of the world market

With the change of economic climate and globalization of competition, mold manufacturing industry has experienced dramatic changes in the past 10 years. Standardized single precision parts have replaced hand-held inserts. Standardized basic parts have been widely promoted and applied. More and more customers have production networks around the world. Mold manufacturers can produce molds reasonably, assemble them as soon as possible, and ensure that there are suppliers of replacement parts worldwide.

1. High standard engineering technology

Only by continuously introducing 3D-CAD design, CAD / CAM and machining center, can the industrial production of mould be realized. Moreover, high speed milling (HSC) and combined workpiece processing have become the latest technology in the field of mold manufacturing. These new developments have replaced the traditional processes such as profile milling and EDM, as well as wire electrical discharge machining (WEDM). The surface quality obtained by HSC milling is high, which makes most time-consuming surface polishing no longer need to be used after EDM. High quality metal removal processes have replaced the separate assembly and alignment of die inserts, instead of centralized assembly.

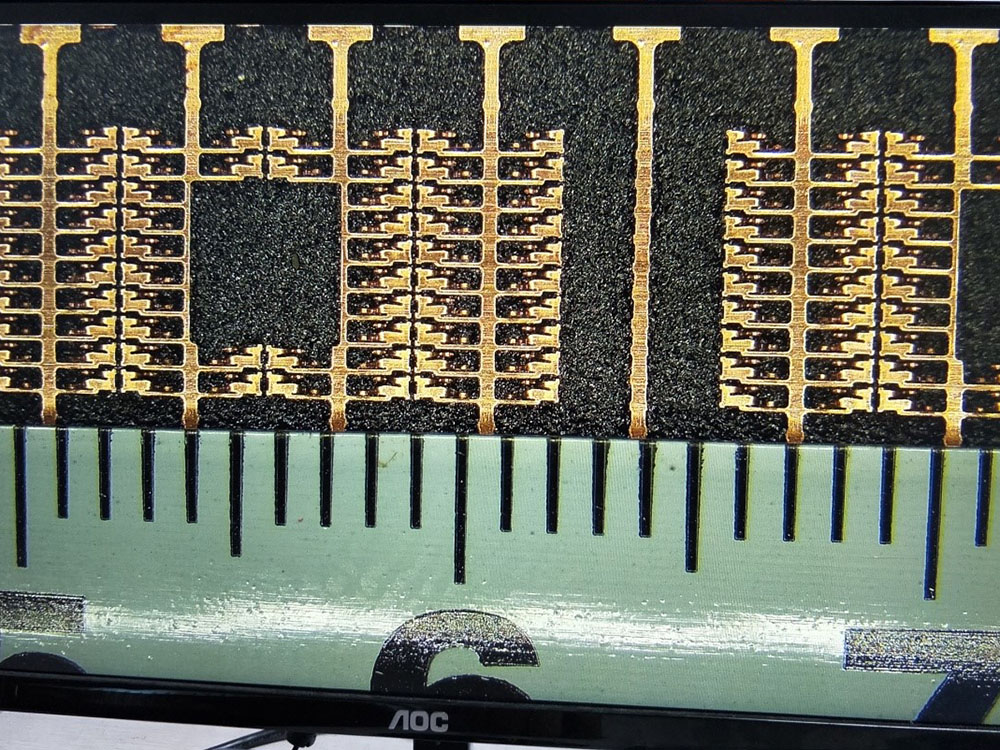

The uniformity and accuracy of the die insert and the female die of the single / multi cavity mold promote the balance of the injection system. The latest technology of injection mold for thermoplastic is hot runner system, while the latest technology of injection mold for elastomer is cold runner system.

2. New injection molding process

The imagination and ability of mould manufacturing designers and production experts have also been tested. They have to translate the many innovations they have made in process engineering over the past decade into successful practices. Examples can be given of multi-material and multi-color injection molding, injection molding with fabric, film or painted surface. However, hot runner system or gas injection method has been used continuously.

The development of these mold manufacturing technologies also requires close cooperation from customers (such as injection molding plants), end users, material and equipment manufacturers. The increasing complexity of molds (the number of cavities, the combination of different processes) has forced mold manufacturing to become more standardized, said Luo Baihui, Secretary General of the International Mould Association. Compared with the situation 10-15 years ago, it is difficult for ordinary mold manufacturers to be competitive in today's market. However, it will be the main task of the mold manufacturing industry to change the product concept and mold design.

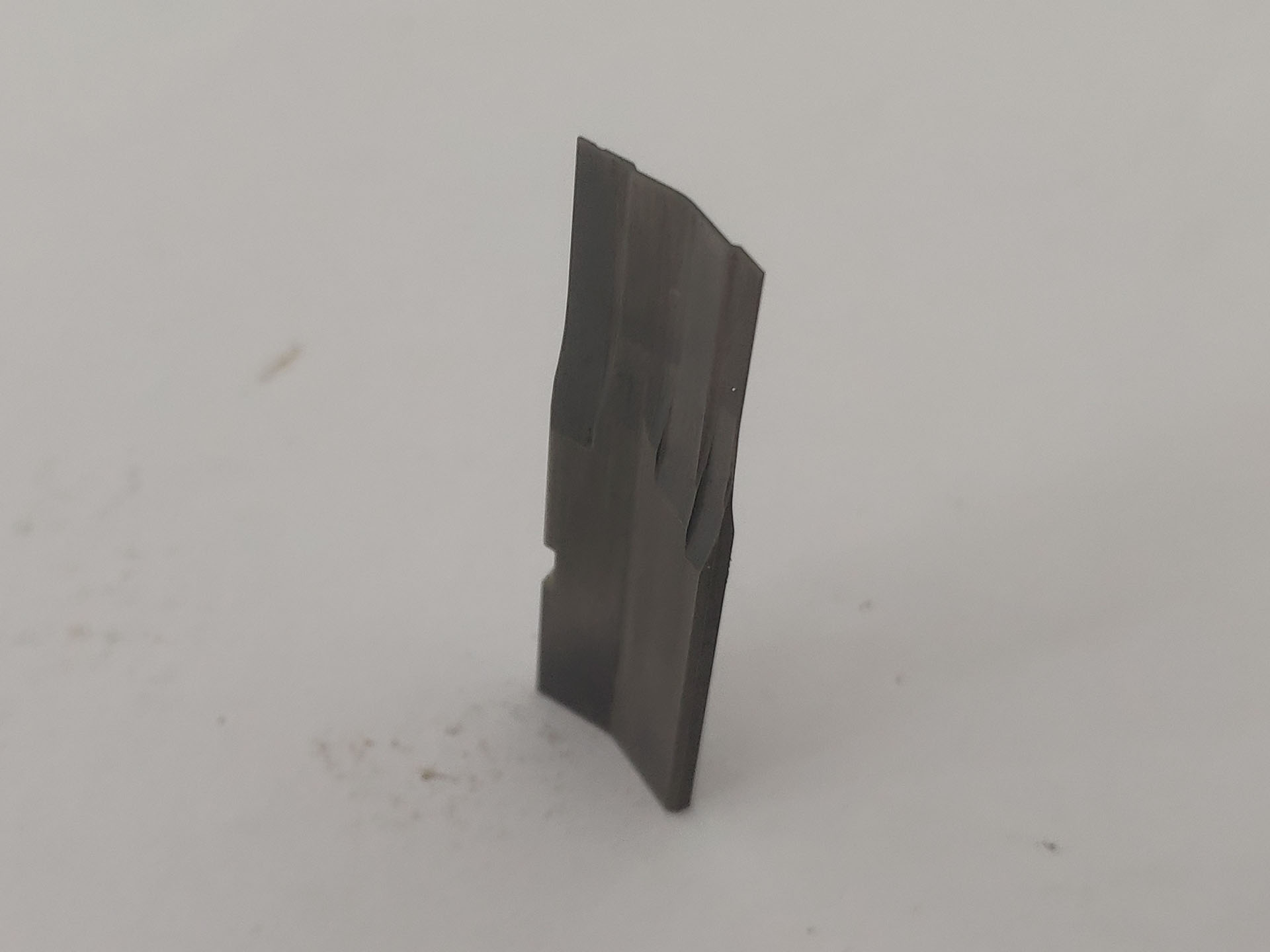

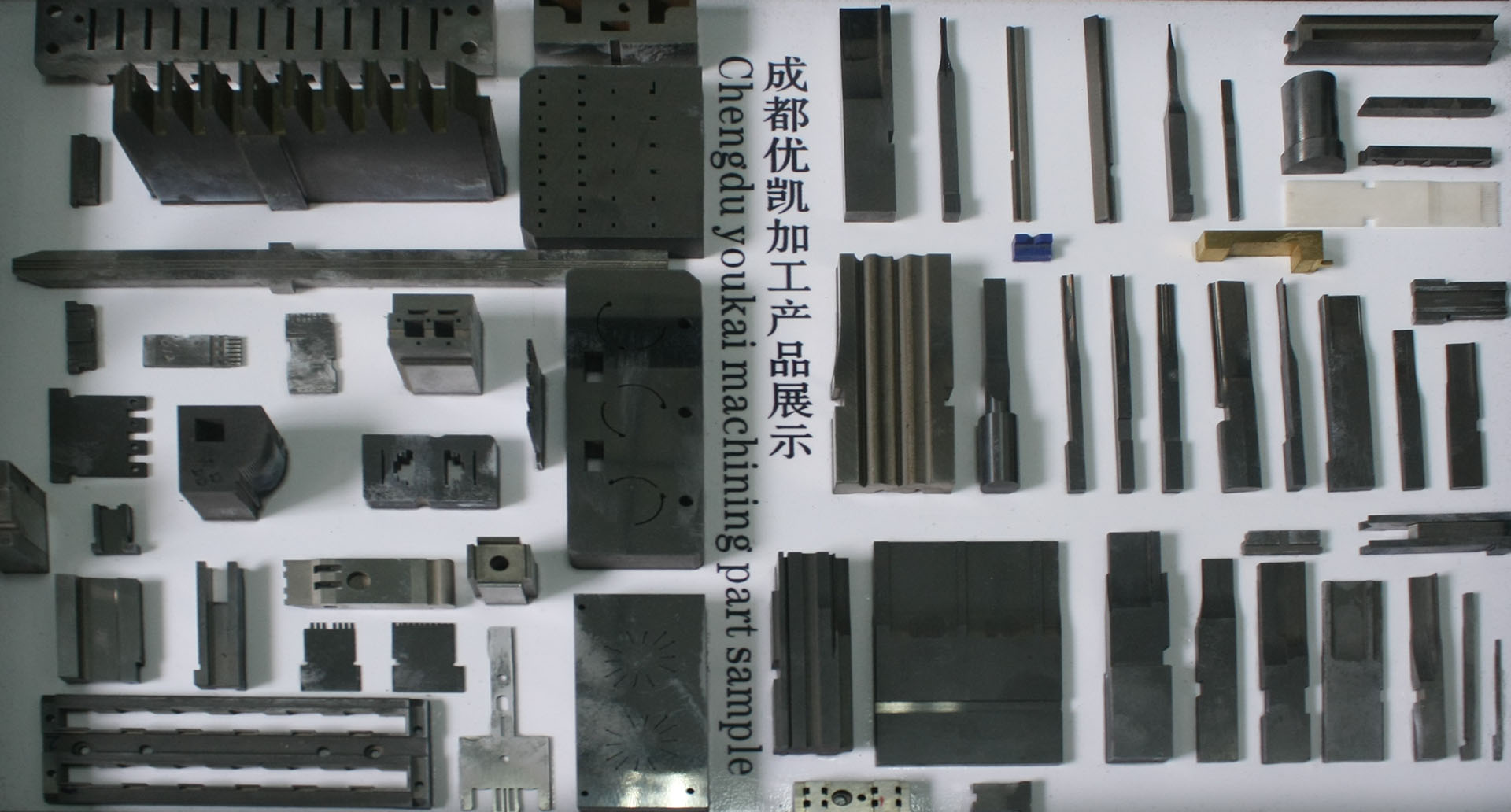

- Recommended products